Coatings contractors use the term mils multiple times per day on the job. But what exactly does the word mils mean? How are mils measured? How do contractors determine the proper mils to apply to a substrate? Read on to find out the answers to these questions and more.

What is a Mil?

A mil is a unit of measurement that equals one thousandth of an inch (0.001 inches). It comes from the Latin word millesimus which means thousandth. Pretty fancy for something that is used every day in the coatings world, right?

However, mils are so important that they are definitely deserving of such an impressive origin. If a coating system is not applied at the correct mil thickness for a particular substrate or situation, the likelihood that the coating will fail increases dramatically. In fact, inadequate mil thickness is typically second only to improper surface preparation when it comes to coatings system failure.

Building Floor Thickness

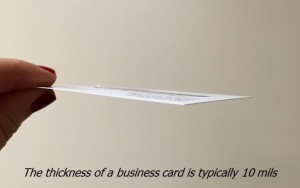

A thousandth of an inch can be pretty hard to imagine, so as a frame of reference, a business card is typically about 10 mils in thickness, a dime is approximately 50 mils thick and a nickel is about 75 mils in thickness. In the coatings industry, epoxy primers are typically laid down at about 7-10 mils, depending on the condition of the substrate and the specifications of the coating manufacturer. The mil thickness of the coating system is then built upon by layering the rest of the coating system (body coat and top coat) on top of the primer coat.

A thousandth of an inch can be pretty hard to imagine, so as a frame of reference, a business card is typically about 10 mils in thickness, a dime is approximately 50 mils thick and a nickel is about 75 mils in thickness. In the coatings industry, epoxy primers are typically laid down at about 7-10 mils, depending on the condition of the substrate and the specifications of the coating manufacturer. The mil thickness of the coating system is then built upon by layering the rest of the coating system (body coat and top coat) on top of the primer coat.

Many epoxy coating systems are approximately 60 mils (1/16 of an inch) when finished. Epoxies are so strong that 60 mils can hold up for years in situations where there is a great deal of foot traffic and even in airplane hangars!

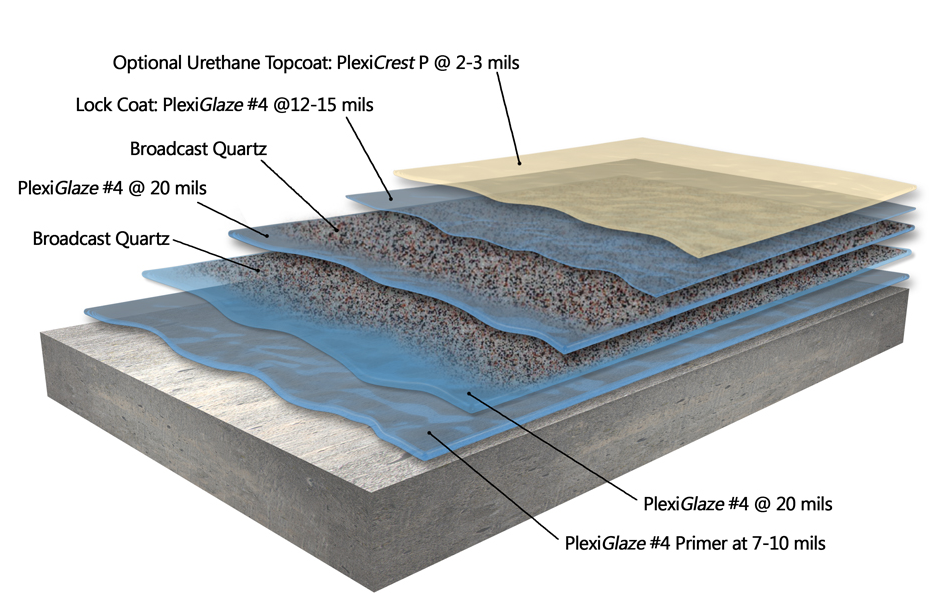

However, in certain situations the coating system needs to be much thicker to provide the required long-term durability. Coatings in commercial or industrial environments are often applied at 125 mils (1/8 of an inch) and a broadcast layer is put down. In other environments, such as a shop floor where forklifts and other heavy equipment are constantly moving back and forth, a 250 mil coating system (1/4 of an inch) may be required. The coatings that are applied in these situations are often called resurfacers and contain one or more broadcast layers.

The PlexiQuartz system is a great example of a flooring system used in an industrial environment that builds thickness of the floor with broadcast layers of aggregate.

Measuring Floor Thickness

So how can a contractor be sure he or she is applying the proper mil thickness with each and every coatings pass? It all comes down to the application equipment. Different types and sizes of rollers for various mil thickness requirements help ensure that applicators are laying down the right amount of coating material, as do squeegees. For large jobs, notched squeegees such as those made by Midwest Rake can be used. These squeegees have inserts that can be placed on their frames to make sure that the correct amount of coating is applied each and every time.

It is also important to remember that testing the thickness is another vital aspect of each and every job. To measure wet film thickness, coatings contractors use a gauge that is serrated on both sides and is cut to different mil thicknesses – 5 mils, 10 mils, 20 mils, etc. The gauge is perpendicularly placed in the wet coating and can give the contractor a precise measurement of the mil thickness of the coating system.

Tip to Remember!

100% solids coatings, such as many epoxies, do not lose any material when dry (wet film thickness is the same as dry film thickness); however, coatings that are not 100% will have some loss of thickness as they cure.

Leave A Comment