CASE STUDY: Surplus Building Floor at NAS Jacksonville Naval Base

Plexi-Chemie Coatings Come to the Rescue on a High Temperature, Quick-Turnaround Job

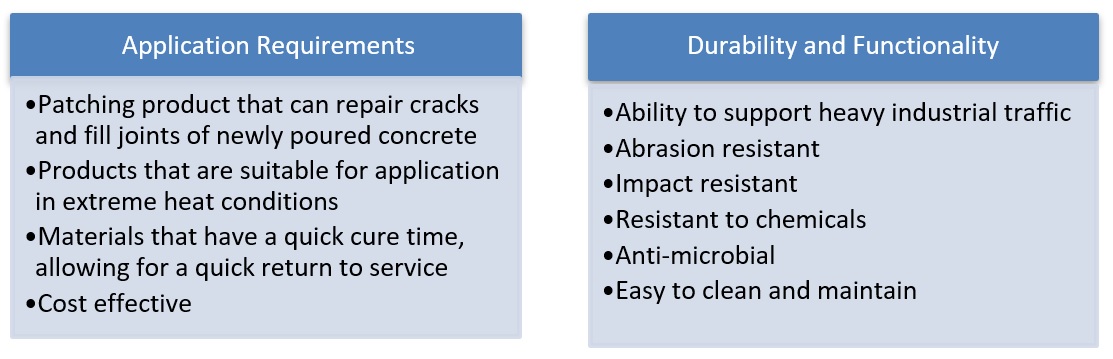

When a naval base in Jacksonville, Florida needed the floor of a surplus building rehabilitated in the heat and in a hurry, applying Plexi-Chemie products were an obvious solution to these challenging application conditions. The building in question was brand-new, as was the concrete floor. However, the concrete cap was not in good shape; there were many cracks and surface deviations to be patched and joints to be filled. The Navy wanted a coating system that would repair the concrete and protect it from damage in the future.

This particular job for the Navy required that the products be applied in temperatures that hovered in the mid-90s. To complicate the application conditions further, the Navy needed the floor completely ready for service in just under a week. Fortunately, not only can Plexi-Chemie materials can take the heat, they are quick to cure and provide a functional and durable flooring system that will last for years to come.

Plexie-Chemie Coatings Rise to the Challenge

A total of 5,000 square feet of PlexiChemie products were installed at the naval base. PlexiPatch QC was applied first to repair the concrete and get the substrate ready to receive the subsequent flooring system, which consisted of one flood coat coat of PlexiGlaze #4, a primer coat and body coat of PlexiGlaze IFF and a final layer of PlexiCrest P, a pigmented urethane top coat.

These Plexi-Chemie products are specially formulated for versatility during the installation process. By adjusting the chemistry of the product and adding hardeners to the coating mix, the workability and cure speed of the materials can be regulated and changed. This versatility means that the Plexi-Chemie products can be applied in extreme heat, slowing down the cure speed enough for proper application, but simultaneously keeping the cure times within the tight timeframe of this job.

PlexiPatch QC is a quick patching epoxy that is used to repair cracks, holes or deviations in concrete. It is also an excellent joint filler. This 100% solids, two-component patching compound is designed for use as a fast repair and setting adhesives on concrete substrates. PlexiPatch QC comes in both a regular version and a flexible version with up to 65% flexibility. Repairs that are made using PlexiPatch QC can be sanded, tapped, drilled, sawed or top coated in as little as 1 ½ hours after application.

After the concrete substrate was rehabilitated and all cracks and joints were filled, PlexiGlaze #4 was applied as a flood coat to the floor of the Navy building. This flood coat conditioned the concrete surface and created the bonding ability for subsequent coating layers. PlexiGlaze #4 is a 100% solids, USDA accepted, clear epoxy floor resin designed for use as a primer/sealer for concrete. It is non-blushing, non-water spotting, anti-microbial and supports heavy industrial traffic. Although the material cures into a very hard solid, it does not become brittle, allowing it to withstand impact and abrasion. It is the most advanced cyclo-aliphatic amine curing system of its kind.

The concrete floor of the Naval surplus building was now ready to receive one primer coat of PlexiGlaze IFF and one intermediate coat of PlexiGlaze IFF. PlexiGlaze Industrial Floor Finish is a non-blushing, non-water-spotting, 100% solids, heavy-duty floor coating especially designed for industrial and commercial applications. It is USDA accepted and is anti-microbial, and although it cures into a very hard solid, just like PlexiGlaze #4, it does not become brittle, but can withstand impact and vibration.

The final layer of the coating system to be applied on this job was PlexiCrest P. This polyester polyurethane gloss coating system is the latest, most advanced technology in coatings for interior/exterior concrete, exterior metal structures, construction industries and equipment protection. The finished system displays exceptional moisture, abrasion and UV resistance, while the hard, slick film is easy to clean. Application of PlexiCrest P provides extended service life compared to conventional urethane coating systems.

Beating the Heat and the Clock

Beating the Heat and the Clock

At the conclusion of the job, the building on the naval base was deemed a flooring system success. The Plexi-Chemie products were installed in just five days, keeping with the Navy’s aggressive schedule. In addition, using products that were suited for the extreme heat kept costs down and meant that the job was done right the first time. It is safe to say that the Plexi-Chemie products used on this project will protect the floor of the building and keep it operational for a long time to come.