Plexi-Chemie Inc 606-6 Lane Avenue North – Jacksonville, FL 32254 Phone: 904.693.8800 Fax: 904.693.8700

About Us

As a manufacturer of resinous flooring systems and wall linings, we pride ourselves on having the strongest floors in the industry. With over thirty years of extensive field knowledge, we have taken our experience and created the best products for you, with the best customer service, at the best price.

Plexi-Chemie has an array of products that fit all of your industrial epoxy flooring needs. Our product line includes primers & sealers, membrane & crack fillers, resurfacers, performance topcoats and our new eco-friendly line. We are the experts when it comes to epoxy, urethane mortars, polyurea, and MMA floors. Our floors are backed with a 5-10 year warranty standing up to rigorous industrial and commercial environments, easy to maintain, sanitary, and safe with a non-skid finish. With an array of design choices, Plexi-Chemie is your one stop shop for Quartz, Crete, and Rubberthane floors.

Plexi-Chemie knows that you want a product that not only exceeds your client’s expectations, but yours as well. We’ve been there and know exactly what you need as an installer.

[dt_fancy_separator separator_style=”line” separator_color=”default”]

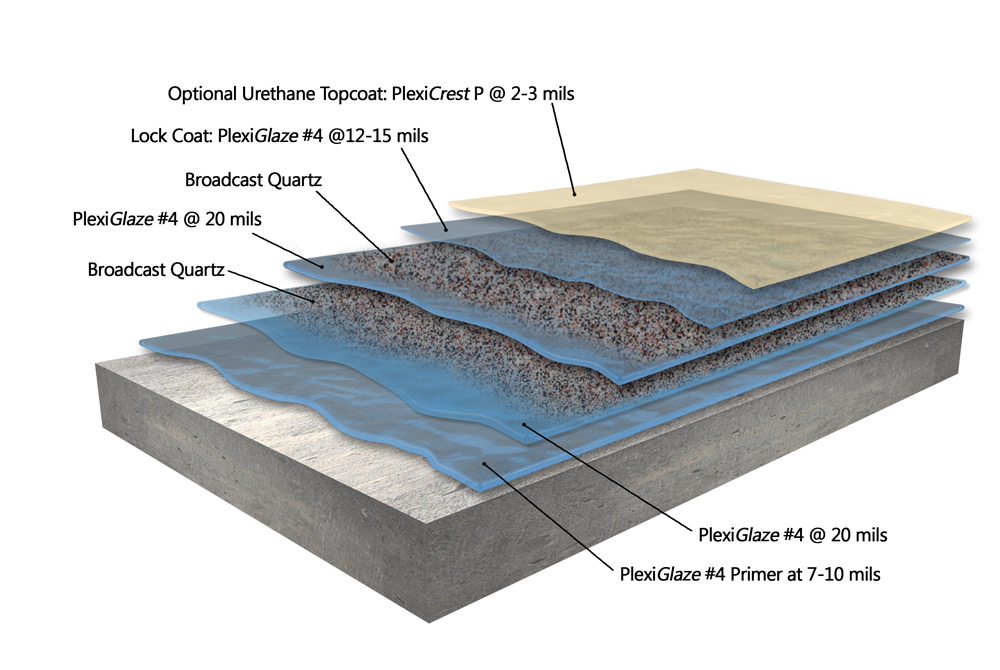

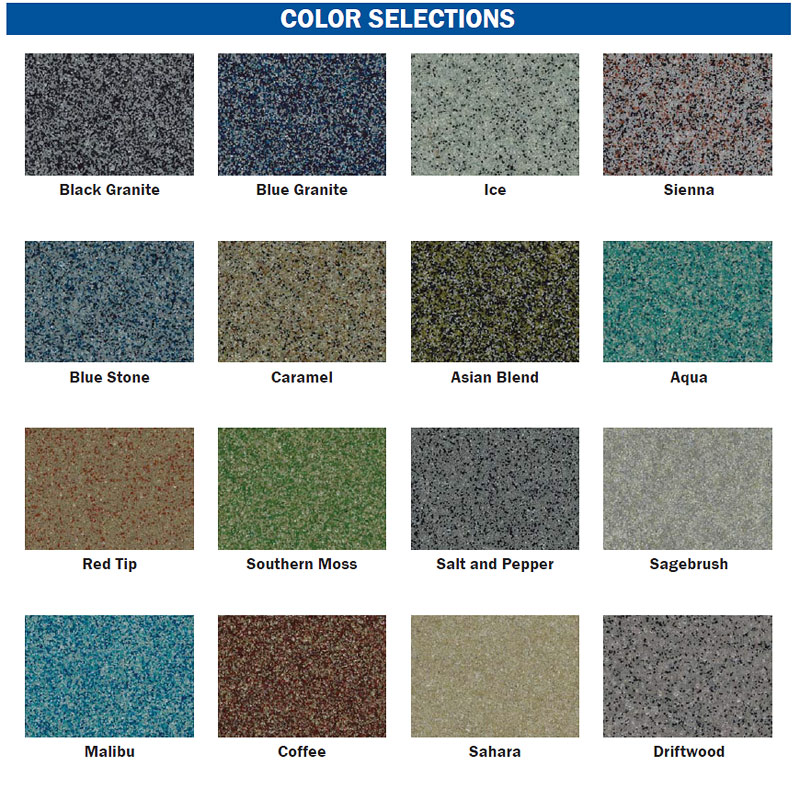

PlexiQuartz™

Seamless Epoxy Quartz Flooring System

The PlexiQuartz system is extremely attractive, durable and chemical resistant. PlexiQuartz is a 100% solids clear epoxy resin and colored quartz flooring system, which is installed at a nominal thickness of 1/8th inch. This system is broadcast skid-resistant and aesthetically pleasing, with 15 blended quartz colors available and 18 solid color blends available. The PlexiQuartz aggregates can be custom blended to create an infinite number of proprietary custom patters. The inorganic naturally occurring quartz granules are color coated using state-of-the-art ceramic coating technology for lasting color stability.

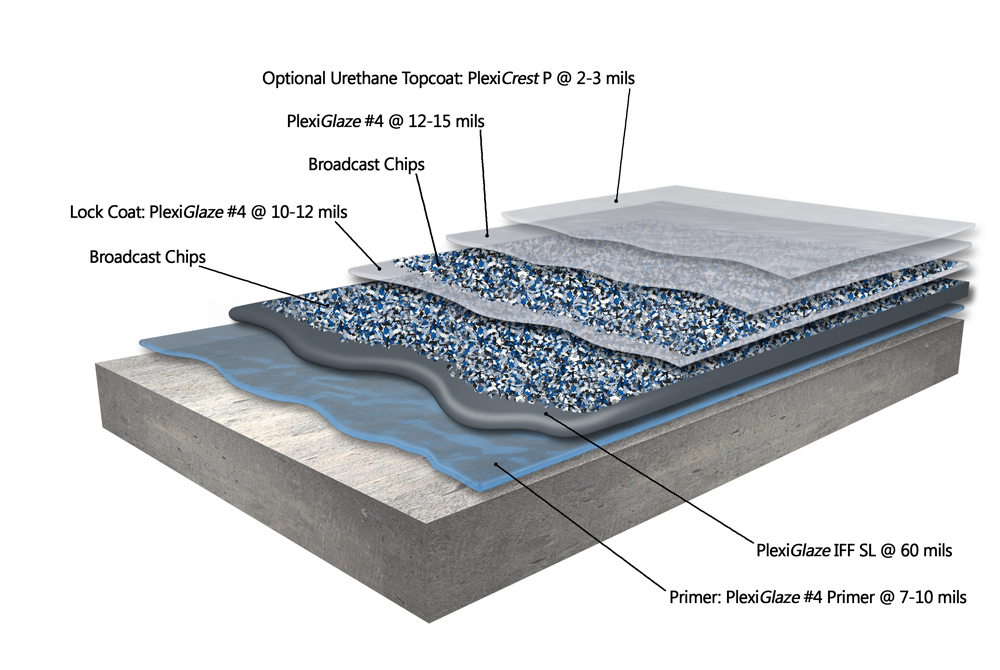

PlexiChip™

Seamless Epoxy Chip Flooring System

PlexiChip is a decorative, “poured in place” flooring system comprised of 1/4 or 1/8th inch decorative chips incorporated into PlexiGlaze #4 or PlexiGlaze IFF. This system is typically top-coated with PlexiCrest P or (for a super thicker top coat) PlexiCrest XP. PlexiChip systems are best used in or for commercial applications. PlexiChip floors provide a terrazzo-like appearance with the benefits of a seamless floor. These floors require no waxing and are easily cleaned. Long term care of PlexiChip floors can be done with renewed additional topcoats. Surface finish can be smooth or slip resistant.

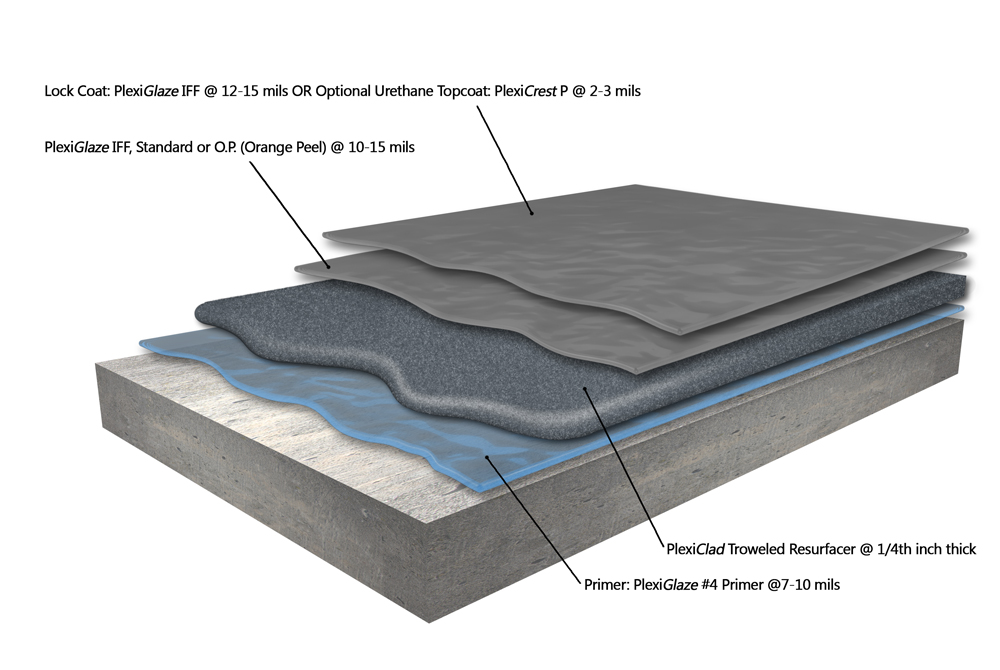

PlexiClad™

Epoxy Troweled System

PlexiClad is a 100% solids, power-troweled epoxy resurfacer. PlexiClad is installed at a thickness of 1/4″. It is designed to rehabilitate worn concrete and as a protective overlayment on new concrete while offering superior protection from heavy industrial traffic (impact, abrasion and compaction). The surface texture can be modified to offer varying degrees of slip and chemical resistance in wet environments.

Urethane Mortar Systems

[dt_fancy_separator separator_style=”line” separator_color=”default”]

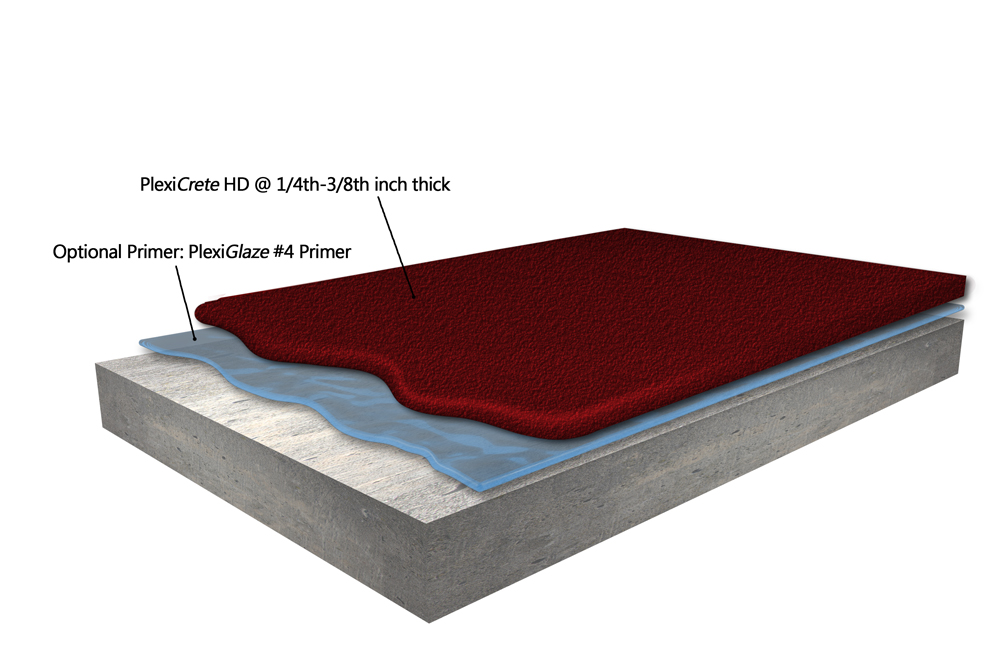

PlexiCrete™ HD

Urethane Mortar Flooring System

[dt_fancy_separator separator_style=”line” separator_color=”default”]

PlexiCrete™ TSLB

Troweled Slurry Broadcast Quartz System

Wall Systems

[dt_fancy_separator separator_style=”line” separator_color=”default”]

GlasLok 170

High-Build Wall-Coating System

[dt_fancy_separator separator_style=”line” separator_color=”default”]

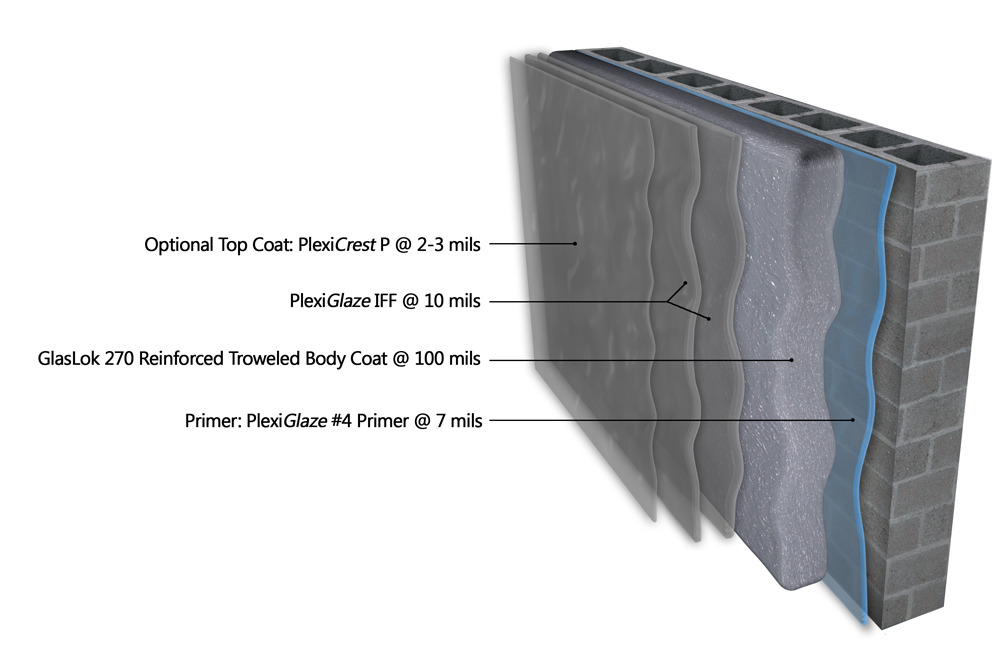

GlasLok 270

Fiberglass Wall-Layup System with Fiberglass Chop Strand

Primers And Sealers – Epoxy

[dt_fancy_separator separator_style=”line” separator_color=”default”]

PlexiGlaze #4

Clear High Performance Epoxy

PlexiGlaze #4 is a 100% solids, USDA accepted, water-clear epoxy flooring resin designed for decorative colored quartz, decorative broadcast flake, a binder for mortar floors and as a primer/sealer for concrete. PlexiGlaze #4 can also be used as a primer, body coat and sealer for walls. PlexiGlaze #4 is non-blushing and non-water spotting, bonds to cold, damp surfaces, and supports heavy industrial traffic. Although it cures into a very hard solid, it does not become brittle but retains a sufficient amount resilience to withstand impact and vibration. PlexiGlaze #4 is the most advanced cyclo-aliphatic amine curing system of its kind. In addition, it is also resistant to fungus, mildew, and is anti-microbial.

Coatings – Epoxy

[dt_fancy_separator separator_style=”line” separator_color=”default”]

PlexiGlaze IFF

Industrial Floor Finish

Moisture Vapor Barrier

[dt_fancy_separator separator_style=”line” separator_color=”default”]

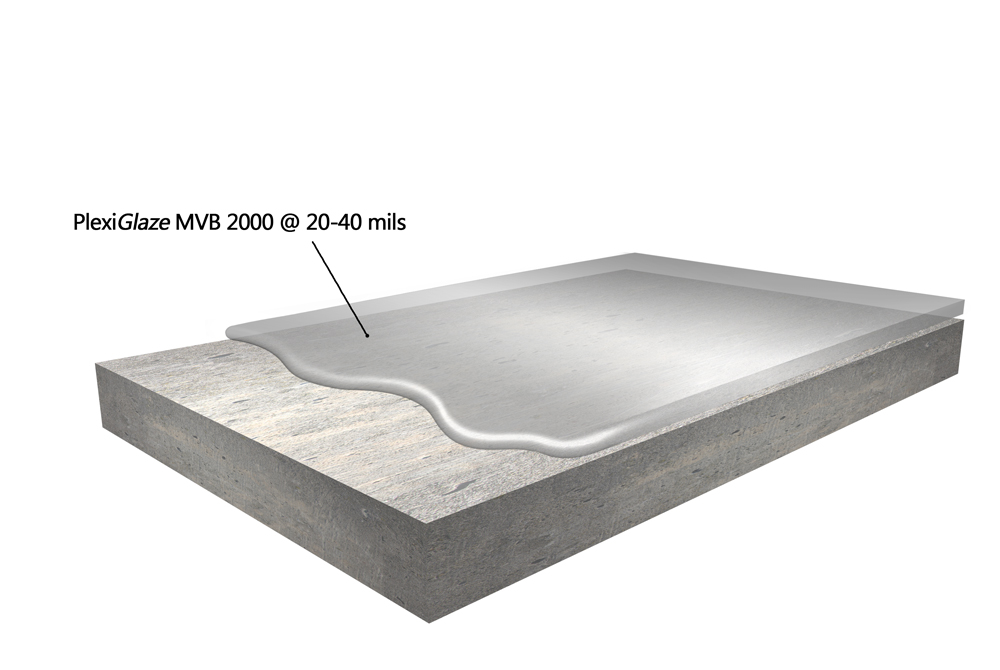

PlexiGlaze MVB 2000 Waterproofing System

A system for the reduction of moisture vapor emission

Urethane Topcoats

[dt_fancy_separator separator_style=”line” separator_color=”default”]

PlexiCrest™ P

Polyester Polyurethane Gloss Finish

[dt_fancy_separator separator_style=”line” separator_color=”default”]

PlexiCrest™ A

Acrylic Polyurethane Gloss Finish

[dt_fancy_separator separator_style=”line” separator_color=”default”]

PlexiCrest™ XP Polyaspartic

Polyaspartic Urethane Coating

Chemical Resistant Topcoats

[dt_fancy_separator separator_style=”line” separator_color=”default”]

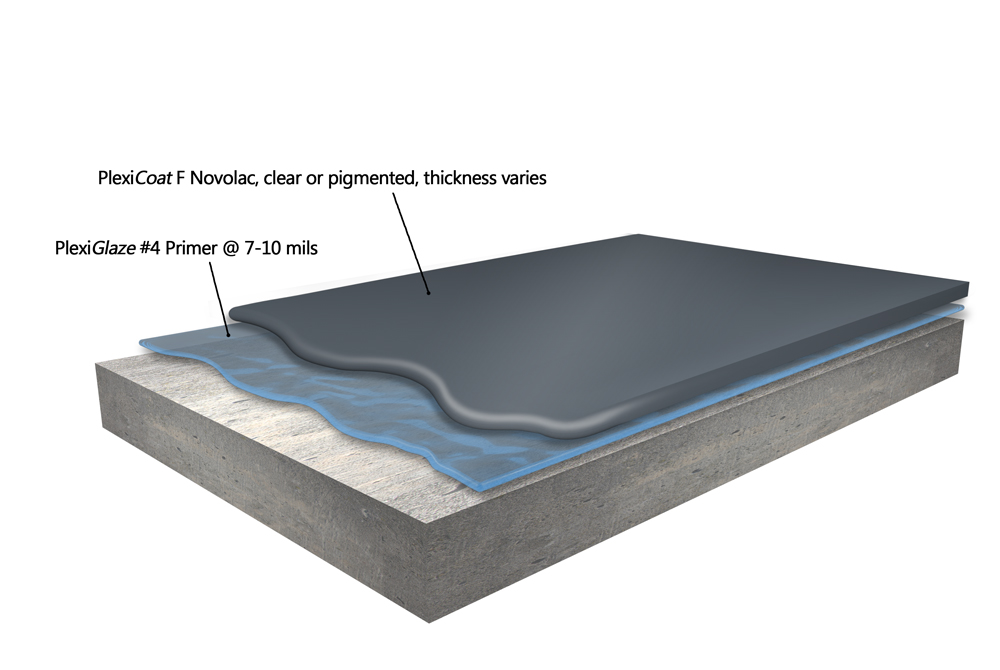

PlexiCoat F Novolac

perly prepared concrete or metal surfaces over epoxy systems to provide enhanced weathering and UV resistance.

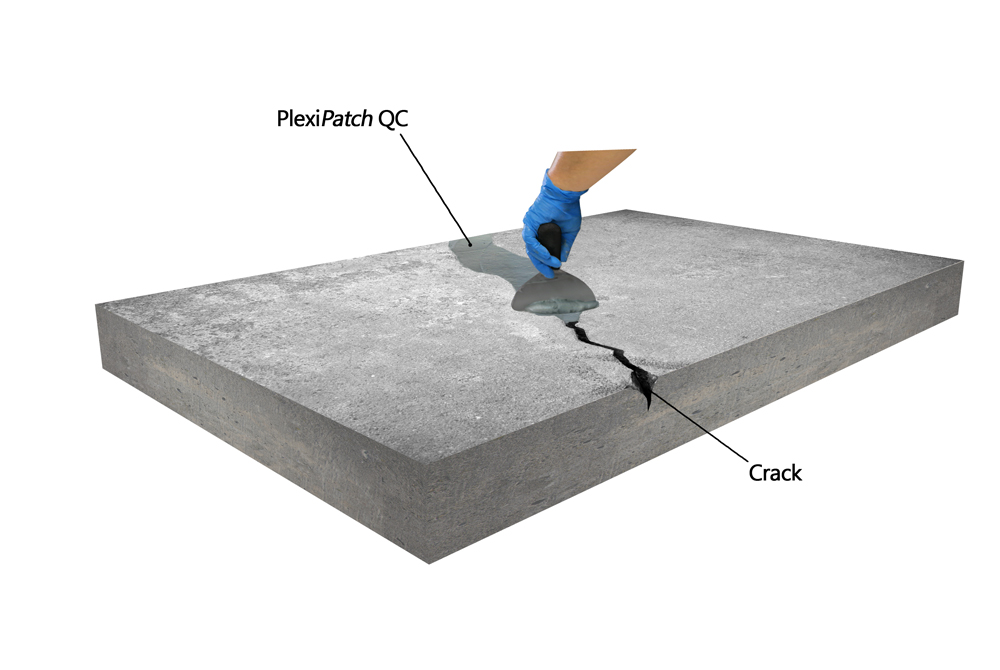

PlexiPatch™ QC

Epoxy Quick Patch Materia

PlexiClad™ Patch Master Kit

The Floor-Clad Concrete Repair Kit is a mortar patching kit used by facilities managers and contractors to repair large holes and divots in warehouse concrete floors.

Floor-Clad Concrete Repair Kit is comprised of:

-40 LB of custom blended mortar aggregate

-1/2 gallon of Floor-Coat IFF pigmented epoxy coating PART A

-1 quart of Floor-Coat IFF pigmented epoxy coating PART B

3″ and 4″ Chip Brushes

Rollers – 9″ & 18″, 3/8th inch NAP

[dt_fancy_separator separator_style=”line” separator_color=”default”]

Stand Up Squeegy 24 & 36 inch

Mil Squeegy Blade

Available in black

5 mil, 10mil, and 20mil

[dt_fancy_separator separator_style=”line” separator_color=”default”]

Poly 3/4 Spikes

Cove Base Tools

Wall Cove Trowel, 3/4 inch radius

Available in 4in, 6in, & 8in

[dt_fancy_separator separator_style=”line” separator_color=”default”]

Roller Frame

9″ & 18″ roller frame

Latex Gloves

Powdered Glove

Sizes – Small to XL

Blue Industrial Grade 4 mil

100 per box