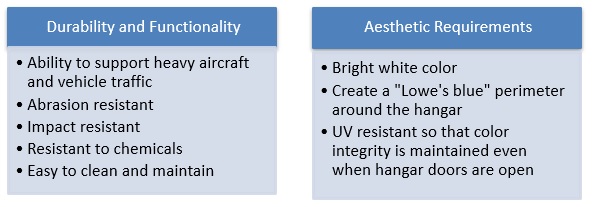

When Lowe’s, the home improvement retail giant, decided to relocate their corporate aviation operations from Statesville Regional Airport to the Charlotte Douglas International Airport, a new 38,000-square-foot hangar was specially designed and built. As a part of this new construction, the concrete floor needed a coating system that would provide abrasion, chemical and UV resistance, along with a beautiful aesthetic that included a bright white color, as well as a 10-foot perimeter in “Lowe’s blue” around the hangar. The general contractor on the job turned to Plexi-Chemie for the protective coating system solution of PlexiGlaze #4, PlexiGlaze IFF and PlexiCrest P. Not only are these Plexi-Chemie materials functional, but they also create a stunning and durable flooring system.

The Right Combination of Coating Materials

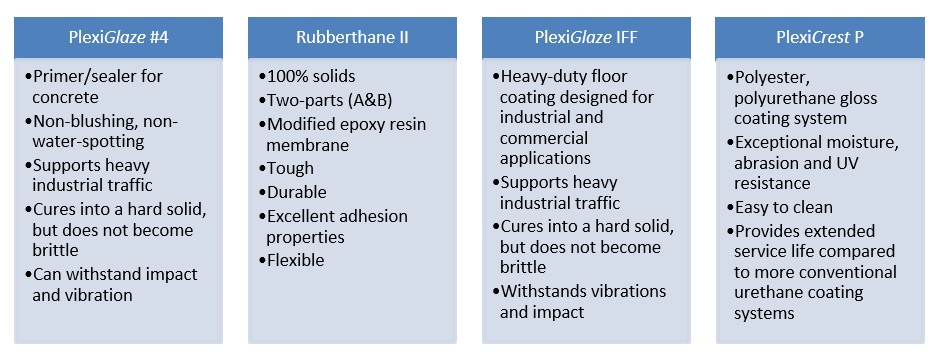

With the hangar floor properly prepped, the crew then got to work applying a flood coat of PlexiGlaze #4 at a thickness of 10 mils. This flood coat conditioned the concrete surface and created the bonding ability for subsequent coating layers. PlexiGlaze #4 is a 100% solids, clear epoxy floor resin designed for use as a primer/sealer for concrete. It is non-blushing, non-water spotting, anti-microbial and supports heavy industrial traffic, including aircraft and support vehicles. Although the material cures into a very hard solid, it does not become brittle, allowing it to withstand impact and abrasion. It is the most advanced cyclo-aliphatic amine curing system of its kind.

After allowing the PlexiGlaze #4 to cure overnight, the crew sanded the floor with a 20-inch buffing/sanding machine. This sanding process allows for the best possible mechanical adhesion by striking out any imperfections and ridding the concrete of any remaining dirt/debris, as well as any sharp areas in the flood coat.

The next step in the process was to repair any cracks in the concrete substrate and treat all expansion joints with Rubberthane II. Rubberthane II is a 100% solids, two-part, modified epoxy resin membrane that is not only tough, durable and has excellent adhesion properties, but is also very flexible. Rubberthane II does not contain plasticizers or any other substances that can separate from the resin polymer over time or degrade due to harsh environmental conditions. Application of Rubberthane II helps to make the expansion joints more flexible and assists in stabilizing movement of the concrete slab. Using putty knives, the crew installed the Rubberthane II at all expansion joints at thicknesses between ¼-inch and ½-inch.

After allowing the Rubberthane II to cure for two to three hours, the crew then applied the body coat of PlexiGlaze Industrial Floor Finish (IFF). This coating is a non-blushing, non-water-spotting, 100% solids, heavy-duty floor coating especially designed for industrial and commercial applications. It is anti-microbial, and although it cures into a very hard solid, just like PlexiGlaze #4, it does not become brittle, but can withstand impact and vibration. Using 36-inch serrated rollers and spiked shoes, the Plexi-Chemie team applied the bright white PlexiGlaze IFF at a thickness of 15-20 mils.

The final layers of the coating system to be applied on this job were two coats of PlexiCrest P in the same bright white color as the Plexi-Glaze IFF body coat. PlexiCrest P is a polyester polyurethane gloss coating system that consists of the latest, most advanced technology in coatings for interior/exterior concrete, exterior metal structures, construction industries and equipment protection. The finished system displays exceptional moisture, abrasion and UV resistance, while the hard, slick film is easy to clean. For this particular job, the excellent UV resistance of PlexiCrest P was especially important, as when the hangar doors are open, the floor is exposed to the harsh, direct sunlight. The crew applied the two coats of PlexiCrest P at a thickness of 3-5 mils per coat using 18-inch and 30-inch rollers. In addition, the crew applied 3-5 mils of PlexiCrest P along the perimeter of the hangar in Lowe’s blue. The beautiful aesthetic will soon be finished off with the installation of the Lowe’s logo in the center of the hangar.

Heating it Up

While the job at the Lowe’s hangar went very smoothly, the December weather did create a bit of a challenge for the crew. During the winter months, the temperature in Charlotte often dips into the 30s or lower. In order to ensure that the temperature inside the hangar was warm enough for the coating system application, roof heaters were temporarily installed and the doors of the hangar remained closed for the seven day duration of the project.

Another Success Story

All in all, the Lowe’s hangar project was a huge success, with the client thrilled with the functionality and durability of the coating system, as well as its stunning aesthetic. Thanks to exceptional materials and a top-notch crew, the Lowe’s executive team can rest assured that the concrete floor of their corporate aviation hangar will be protected well into the future.

Leave A Comment