When it comes to moisture content within concrete substrates, it’s all about water and pressure. Water is the lifeblood of concrete—without enough water in a concrete pour, the substrate is weak and will crumble. However, if a concrete slab contains too much water, pressure will force the moisture to the surface, creating a substrate condition that is not conducive to the proper adhesion of the epoxy floor resin that is to be applied. (Epoxy floor coatings that are applied to substrates with too much moisture are subject to delamination and ultimately to complete coating system failure). When too much moisture exists within the substrate, a moisture mitigation system such as PlexiFloor Epocrete must be installed.

How does a system like PlexiFloor Epocrete work to block moisture vapor transmission? To truly understand the chemistry involved in the Epocrete system, it is important to first take a look at the composition of concrete, as well as how to determine the moisture content within concrete substrates.

[dt_fancy_separator separator_style=”line” separator_color=”default”]

What’s In a Name?

Although many people use the terms concrete and cement interchangeably, one is actually part of the other. Cement is the powder that is mixed with water, sand and aggregate to create concrete. When cement is added to these other ingredients, a chemical reaction takes place that binds them together and forms a concrete substrate. Depending on the thickness of the concrete pour and environmental factors such as ambient temperature and the humidity of the air, concrete typically takes several weeks to cure. Even after this time, a cured concrete substrate can still contain almost two-thirds of the moisture from the original mixture. This amount of water is too much for a coating system to adhere properly to the surface. Over time, the concrete continues to dry through moisture vapor transmission. The pressure within the porous substrate draws moisture up through capillary action to the surface of the slab, where it evaporates into the atmosphere. The only way to determine if concrete is dry enough to receive a coating system or if moisture mitigation is necessary is by conducting moisture testing.

[dt_fancy_separator separator_style=”line” separator_color=”default”]

Taking the Test

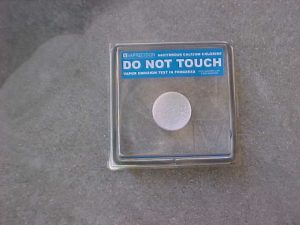

The most common test to measure the moisture vapor emission rate (MVER) is the calcium chloride test. This test is typically administered every 1,000 square feet, and consists of sealing a small dish of calcium chloride under a plastic dome on a clean section of concrete. The salt absorbs the moisture under the dome over the course of 72 hours. At that time, the weight gain is calculated and used to determine the MVER. This method is described in ASTM F1869.

Another form of testing is the relative humidity method, where in situ probes are inserted into holes drilled into the substrate. This method is described in ASTM F2170 and measures the moisture content within the substrate, rather than just at the surface.

[dt_fancy_separator separator_style=”line” separator_color=”default”]

Other Considerations

Although it may seem as if moisture issues only occur within newly poured concrete, older concrete slabs can also require moisture mitigation. If the concrete was not allowed to cure properly when it was originally poured, too much water was in the mix or the vapor retardant that was placed underneath the concrete was faulty, a major moisture problem could be hidden within the concrete’s porous composition. For this reason, moisture tests should always be performed prior to the application of any coating system, regardless of age.

In addition, certain areas of the country are more prone than others to vapor transmission within concrete. Florida, for example, has a high water table, meaning that the earth is saturated with water not far from the surface. With all of this water just beneath the ground, it is not uncommon for concrete slabs to have high rates of moisture vapor transmission.

[dt_fancy_separator separator_style=”line” separator_color=”default”]

The Moisture Solution

If the calcium chloride test at a jobsite comes back with moisture levels that are too high for the application of an epoxy floor coating, it is time to mechanically prepare the concrete substrate and apply EpoCrete. Epocrete is a three-component, water-based, solvent-free, moisture tolerant epoxy and high performance cementitious self-leveling slurry mortar. The EpoCrete specially formulated chemistry takes the standard A and B components (epoxy and emulsion hardener) and mixes them with a C component that is a cement copolymer. This cement copolymer cross-links with the water in the concrete substrate and creates a bond that is greater than the pressure trying to move the moisture upward. In other words, the EpoCrete blocks the water from coming to the surface and orients it laterally throughout the substrate. In this way, the EpoCrete creates a vapor barrier and readies the substrate for the application of Plexi-Chemie epoxy floor coatings.

[dt_divider style=”thin” /]

For more information about PlexiFloor EpoCrete, please contact a Plexi-Chemie sales representative, or feel free to call us at 904-693-8800 or email us at office@plexi-chemie.com.

Thanks for this helpful piece of information.