Few things make a coatings contractor cringe like the words “moisture vapor emission.” However, moisture problems in concrete substrates are common, especially in areas like Florida where the water table is high. Moisture problems must be dealt with BEFORE applying a coating system. If concrete contains too much moisture, a coating system will not properly adhere to the substrate and can possibly lead to complete coatings failure.

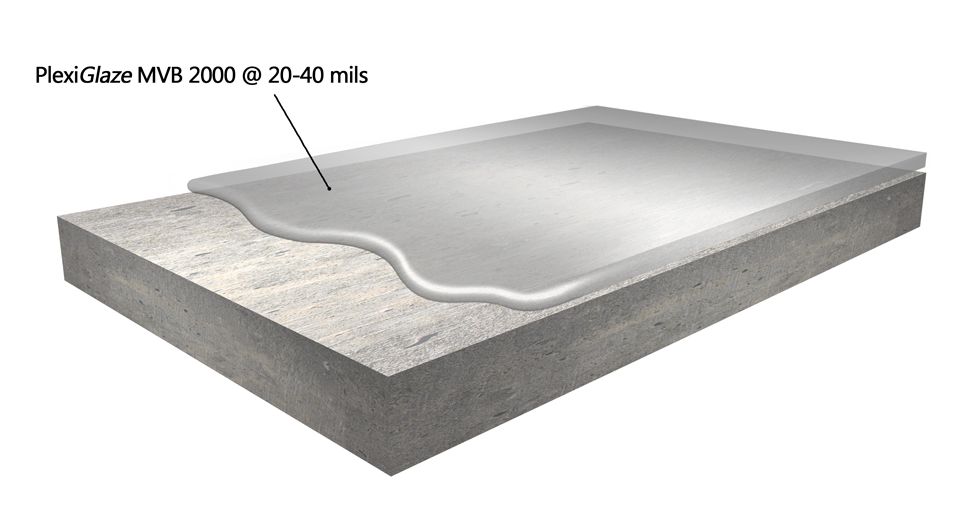

So what’s the answer to stopping moisture vapor emissions before they become an even bigger problem? PlexiGlaze MVB 2000 is a moisture mitigation solution reduces water vapor and moisture levels to an acceptable level and is a long-term solution to ensure proper coating system adhesion.

What is PlexiGlaze MVB 2000?

PlexiGlaze MVB 2000 is a one-coat system which consists of a unique combination of epoxy resins and other chemical substances. It is specifically formulated to overcome the inferior adhesion properties of most resin-based systems when curing in an environment of constant wetness, extreme alkalinity and vapor drive. Because of its extreme density, it is capable of reducing water vapor and moisture to levels that are acceptable for the application of most coatings, adhesives and floor covering systems.

In other words, PlexiGlaze MVB 2000 is the first step in applying a high performance, long-lasting coating system on substrates that have moisture issues. As far as moisture mitigation is concerned, it is the first line of defense.

Advantages of PlexiGlaze MVB 2000

[dt_gap height=”20″ /]

When deciding what type of moisture mitigation system to use, coatings contractors need to consider many factors, including the VOC levels of the product, its chemical properties and its compatibility with other coating materials.

PlexiGlaze MVB 2000 is in full compliance with current VOC regulations, has excellent chemical and abrasion resistance and is compatible with most 100% solids epoxy and/or polyurethane-based coating materials. These characteristics are just a few of the reasons why PlexiGlaze MVB 2000 has a proven track-record of moisture mitigation.

Proper Surface Prep: A Must

It can never be stated enough – a coating system (or moisture mitigation system in this case), is only as good as the surface preparation of the substrate. In order for PlexiGlaze MVB 2000 to achieve optimum performance, the substrate must be properly prepared. All surface contaminants must be removed completely by shot blasting to ICRI CSP 3 or CSP 4 finish. Only a surface that remains sound, clean, absorptive and free of all types of contamination is fit to receive PlexiGlaze MVB 2000.

[dt_divider style=”thin” /]

For more information about PlexiGlaze MVB 2000 or other Plexi-Chemie products, please click here or call 904-693-8800.

Leave A Comment