As any coatings contractor will tell you, epoxy resin floor coatings are durable, chemical resistant and cost effective solutions for a wide variety of situations. However, what should a contractor do when a coating with even more chemical and thermal resistance is required? Read on for information about the excellent chemical and heat resistant properties of the PlexiCoat F Novolac epoxy coating system.

Chemistry Lesson

In order to understand the characteristics of Novolac epoxy coatings, you need to look at the chemistry behind them. All epoxy coatings consist of two components that react with one another – Part A which is an epoxy resin and Part B which is a curing agent (also called a hardener). Part A and Part B are cross-linked in order to develop the epoxy coating’s required properties.

Novolac coatings are unique, however, in their functionality. Functionality is the term that refers to the relative number of reaction sites for the resin’s chemical backbone. The higher the functionality of a resin, the greater its cross-link density. Cross-link density is what determines chemical resistance.

Novolac epoxies have a higher functionality than traditional epoxy. Without delving too deep into the chemical makeup of these coatings, regular epoxy resins are made with bisphenol A (BIs A). The simplest form of Novolac epoxy resins are made from bisphenol F (Bis F). The reaction between Novolac epoxy resin and the hardener produces a unique chemical structure that results in high functionality and a tightly cross-linked system. Looking at it another way, unlike regular epoxy resins, Novolac coatings have both linear and perpendicular linkage in their chemical make-up. This chemical cross-linking produces coatings with much greater chemical and thermal resistance.

Under Attack

In harsh environments, corrosive materials attack the chemical chains of a floor coating. The tighter the chains (or cross-links), the more likely it is that these corrosives will bounce off the surface. The tightly cross-linked chemical backbone Novolac coatings improve resistance to acids, bases and solvents and maintain the retention of mechanical properties at high temperatures. Even in high concentrations, corrosives (including acids and solvents) will not break down the coating material.

However, it must be noted that with all of the superior performance characteristics of Novolac epoxy systems, they are more expensive than regular epoxy coatings. This means that budgetary constraints need to be taken into account prior to specifying a Novolac coating system.

When PlexiCoat F Novolac is the Right Solution

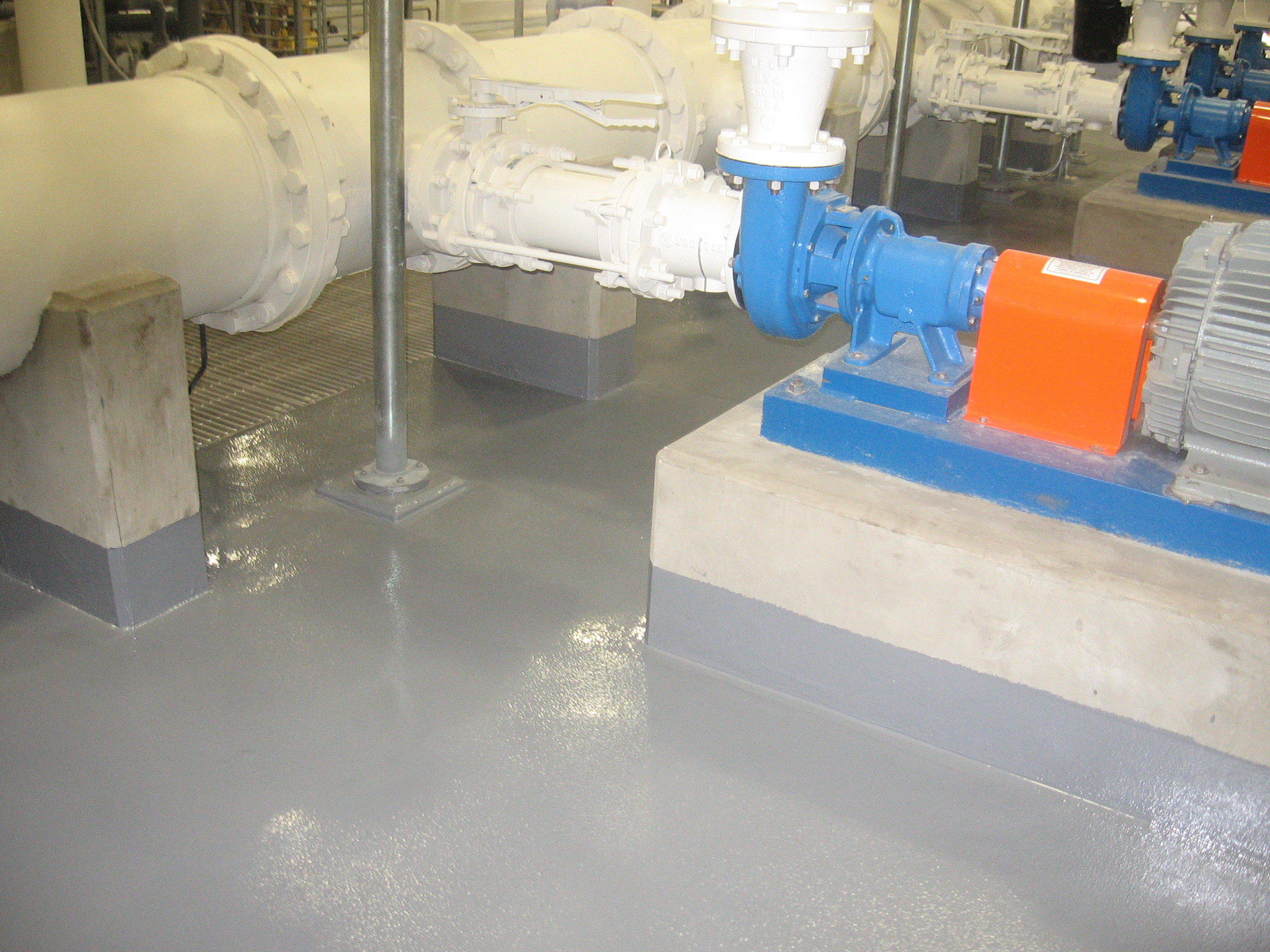

As previously mentioned, some environments are exceedingly harsh and require a material such as Plexi-Chemie’s PlexiCoat F Novolac that has extreme chemical and thermal resistance. These types of environments include battery storage areas, chemical storage areas, industrial kitchens, food processing plants, secondary containment areas, tank linings, power plants, wastewater treatment plants and any other areas that are susceptible to chemical spills or extreme heat. PlexiCoat F Novolac is designed for service in these challenging environments.

[dt_divider style=”thick” /]

For more information about PlexiCoat F Novolac and its excellent chemical and thermal resistance properties, please visit www.plexi-chemie.com/epoxyfloorcoatings/ or call (904) 693-8800.

Leave A Comment